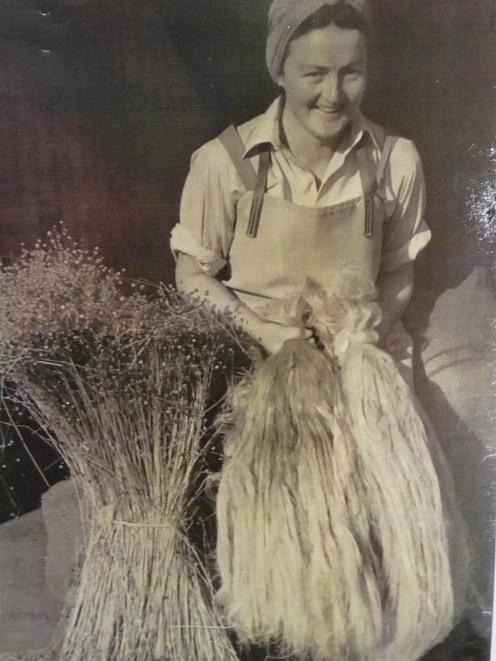

Linen flax, a fine, soft plant with a pale blue or white flower and a very small seed was planted, grown and harvested in the wider Methven area from 1940, and then processed in a purpose built factory on Carr Street, (off Racecourse Avenue). Part of the factory exists today,

Much of the Methven factory burnt down in September 1948 and the production wrapped up the following autumn.

The story of Methven's flax linen production is explained in a display set up at Methven Museum.

Material for the exhibition has been taken from local archives and also borrowed from Geraldine Museum.

The exhibition has been researched and curated by museum member Jeanette McLennan, who says it has provided her with a fascinating insight into a former industry that had a sizeable impact on the local economy and people for nine years.

Mrs McLennan said she was grateful for the support of the Geraldine Museum, which had provided advice, information and exhibits.

A similar linen flax factory had been built in Geraldine in 1941 and had continued to operate until 1981.

In its heyday the Methven linen flax industry employed a core workforce of 40-60 people and up to 94 workers from around the district at busy times, she said.

Some 70 growers and 2000 acres of land was used, before the decline in demand for the product.

Linen flax was used for a number of purposes, including for flexible fire hoses, to cover the fuselage of Hurricane fighters and Wellington bombers and for linen canvas and ropes for the navy.

Mrs McLennan said growing trials had been carried out in New Zealand and the contract with the British government had been for 15,000 acres, although more than that was grown across the South Island.

She said processing the fibre was a complicated and time consuming process.

"They stacked and stored it and then took it to the factory to de-seed and dry it out.

"A process called 'retting' submerged the bundles of stalks in water at between 32 and 34 deg. C. to help separate the fibres from the stem.''

The final process of "scutching'' removed the broken woody pieces (shives) by beating and scraping.

Only the high quality, long fibres, 20 inches (51cm) in length were twisted into hanks, tied into bundles and pressed into bales for shipping overseas, said Mrs McLennan.

She said processing linen flax produced a lot of effluent and around 22 per cent of crops had been rejected for one reason or another.

New Zealand supplied 10,274 tonnes of linen flax to the British between 1941 and 1948.

The Methven flax linen exhibition runs until November and will be followed with a display about the former Methven Maternity Hospital.

Methven Museum is open Tuesdays and Fridays from 2pm until 4pm.