OFF-PADDOCK INFRASTRUCTURE

In the second of a three-part series, Shawn McAvinue visits Southland dairy farms using different types of off-paddock infrastructure for calving, wintering, feeding and stand-off management. This week, Isla Bank farm owners and operators Tom and Kate Severn show their feed pad and wood chip calving areas.

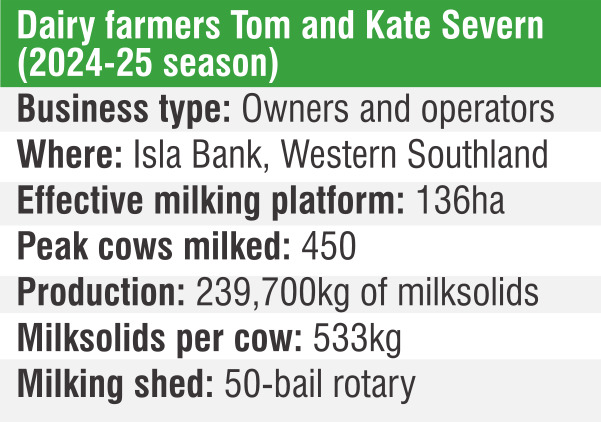

The herd on Tom and Kate Severn’s dairy farm in Western Southland set a new production record last season.

If there was any secret to producing more than 530kg of milksolids per cow, in a season featuring a wet start, it was the feed pad.

"I put 90% of it down to the feed pad after the spring we had," Mr Severn said.

The pad allows them to give the herd more feed, which helps boost production, he said.

Mr Severn left a banking job so he and his wife could go 50:50 sharemilking on her family’s dairy farm.

They bought the farm from her family last season.

Existing infrastructure includes a concrete pad, featuring two 70m-long feed bins.

All of the silage and baleage for the cows and straw and hay for the heifers was brought in.

Buying feed allows them to have a high stocking rate, 3.3 cows per hectare and limit nitrogen-use to 122kg per hectare.

He once ran out of silage in September and found sourcing a constant high-quality supply was a challenge.

Consequently, he bought palm kernel and an auger bucket to attach to his tractor to put it in the feed bins.

"With the bucket I could feed out one ton of palm kernel on top of some silage and it took five minutes to do and it was the equivalent of five and a-half bales of feed."

Throughout the year, the cows being milked are fed in the shed an even mix of palm kernel, rolled grains and distillers' dried grains.

A benefit of a feed pad is keeping tractors off muddy paddocks.

The feed pad was "worth its weight in gold", he said.

Their pad is on a sideways slope, so they were unable to retrofit a green wash system.

If he built another, he would have it sloping either up or down so it could include a green wash system.

Any effluent or feed dropped on the pad by the herd needs to be scrapped daily, using a tractor with a blade attached, which took about 20 minutes.

Cows spent a minimum of six hours on the pad in spring last year, which was very wet.

The herd is milked twice a day and spends three hours on the pad after leaving the shed.

Being able to put the cows on a pad gave all staff a chance to take a breath, he said.

"We bought a lot of time with it and more time gives you less stress when it is that busy."

Cows which have eaten on the pad and are more than 80% full will lie down rather than forage when put on a paddock, which has benefits for the paddock and animal health.

About 400 cows can eat from the 280m-feed face at the same time.

Cows are only allowed on the pad after being milked or during a major weather event.

When a cow has eaten enough, she will rest on an area covered in wood chip at the back of the feed pad.

"If the weather is really bad, we’ll put all the milkers on the pad overnight and they can sit down on the bark chip and feed as they want to through the night."

The bark chip area allows for 450 cows to be put on the wider feed pad area at the same time.

To know the herd was on the pad, rather than in a paddock, during bad weather, made it easier to sleep, he said.

Cows can calve on an area of woodchip, about 80m by 10m, to the side of the pad and are given access to an outside feed lane.

The milking herd is given access to the middle lane of the pad.

Minerals are put in the feed bins depending on which animal has access to it.

Empty cows are put in a paddock and fed grass and baleage.

Other infrastructure on the farm includes a calving barn, which was a former covered yards and had lighting, which was "handy" when it was wet and dark outside.

Another uncovered woodchip area is for heifers and cows having calves which will not be part of the herd.

"So you don’t have any mix-ups on the ones you want to keep and don’t want to keep."

The extra expense to be able to easily lift a calf from wood chip and load it on a trailer when it was raining was worth it, he said.

"It outweighs calving on mud."

He paid $32,000 for wood chip from Pankhurst Sawmilling in Riverton.

The wood chip is expected to last three years.

"It lasts if it is managed properly."

He bought wood chip from the sawmill each year to ensure a continuation in supply.

"There is such a high demand for wood chip, if you don’t get some each year, you get put on the bottom of the list."

When Southern Rural Life visited, about 470 cows wearing smart collars were being wintered on kale and pit silage in Dipton.

Mr Severn had considered covering the concrete yard to winter the herd on farm.

To cover the yards would cost about $600,000 and a consent would be required to winter the herd.

The cost to winter the cows on farm in covered yards was not worth the investment when compared to the expense of the existing wintering system in Dipton.

The farm has a consent to run up to 500 cows but there is no plan to increase the herd size and feed more to increase production.

"Ethically do you really want to do that? Or are you happy with what you are achieving and we are."