Off-paddock infrastructure

In the first of a three-part series, Shawn McAvinue visits Southland dairy farms using different types of off-paddock infrastructure for calving, wintering, feeding and stand-off management. This week, Waianiwa sharemilkers Jeremy and Michelle Smith highlight a new concrete feed pad.

A new concrete feed pad is "future-proofing" a dairy farm business in Western Southland, sharemilkers Jeremy and Michelle Smith say.

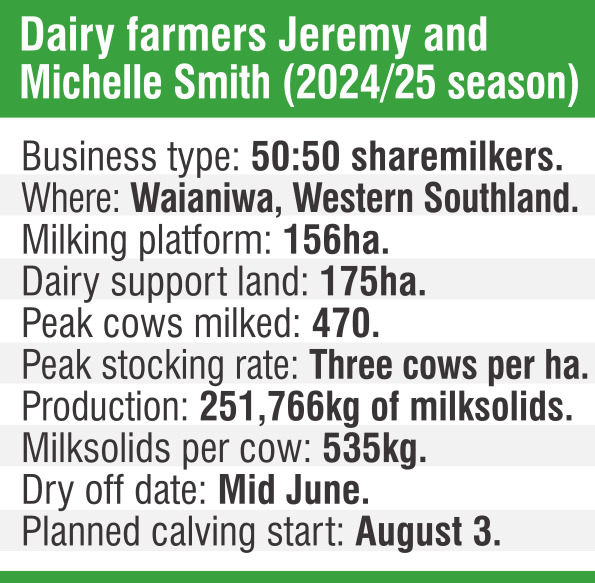

The couple are in their 10th season sharemilking 480 cows on 156ha in Waianiwa.

As 50:50 sharemilkers, they own the cows but do not own the land or have any control of the infrastructure installed on the farm.

The Smiths own a 100ha dairy farm, milking 320 cows about 10km north of Waianiwa.

Mr Smith said when they bought their farm it had a pad with feed troughs, which allows them to milk their cows in winter.

"We’ve seen the huge benefits a winter pad can bring to a farming system"

Herds on both farms wore Allflex smart collars.

Data from the collars showed cows fed on the pad in wet conditions ruminate more quickly than cows foraging in a paddock.

"By sending a cow to a paddock full, their time foraging is so much less"

A full cow uses its time in a paddock to rest rather than forage, which reduces damage to pasture and maintains milk production.

The benefits of the feed pad on the other farm, made them realise some off-paddock infrastructure was needed in their sharemilking operation.

"We called a meeting with the farm owners to see what their appetite was for putting infrastructure on"

His wife set a meeting agenda and obtained quotes for possible options because a "rough answer" was wanted on the day, Mr Smith said.

The pad was "future-proofing" the business by maintaining animal health and operating sustainably, he said.

"If we plan to stay in the industry we need to keep up, otherwise we’ll be left behind and what was happening this spring was not good enough and I didn’t want to be in that position again"

He recalled driving a tractor, towing a silage wagon and getting stuck in mud, sparking fears he would not be able to feed his cows.

"We are in the game to keep cows happy"

A pad allows him to feed palm kernel to his cows.

He would never feed palm kernel in a paddock because it would be challenging to make sure each cow got its fair share from a trailer.

The farm owners agreed on installing a concrete pad with feed lanes and set a budget in spring last year.

"It has been a slow, drawn-out process ... there were a lot of dominoes, where a job couldn’t be done until somebody else had done their bit"

Good weather had helped the progress of the project.

The original plan was for the feed pad to be ready for use in autumn this year but that deadline had passed.

He hoped the pad would be used for the first time by the end of this month.

Each feed lane could be flood-washed.

Green wash was released from tanks at the top of the pad, the liquid moving effluent on the pad to a sump at the bottom.

He would make sure the greenwash contained enough water and not have too much effluent to avoid the liquid being a slipping hazard for his cows.

A cutter pump shifts liquid from the sump up to two holding tanks above the pad.

If the pump was out-of-action from a power cut, the sump had an overflow pipe to move the effluent to a weeping wall effluent system.

Before the concrete was poured on the pad, strong wind in June this year lifted empty greenwash holding tanks.

At the same time, a power cut stopped the cutter pump working, which resulted in the sump overflowing.

The tanks, which were stropped down, were damaged beyond repair and replacements took six weeks to arrive.

New tanks were filled with some water to avoid a repeat when strong winds return.

The design of the feed pad features lanes, rather than troughs because it takes less time to clean lanes, as staff could use a tractor to do the job.

A disadvantage of a feed lane was cows pushing feed out, which would then require it to be pushed in.

Each of the outside lanes could be split in four sections.

"You can have colostrums at one end, springers at the other end and the other lane can be for milkers. A big thing was to have options"

By spreading out the cows in the two lanes would ensure all of the herd had access to the same amount of feed.

The cost for the project were still being tallied but he hoped it would be no more than $1100 per cow.

"We worked as hard as we could to get some fixed costs but there is so many variables"

A future plan could be to install some rubber matting in a lane for cows to calve on.

Their son George broke his leg skiing on the last day of the latest school holidays.

"He’s not going to be the calf-rearer this spring, unfortunately," Mr Smith said.