The engine is the Leyland type for heavy commercial work. It has six cylinders, bore and stroke being 5½ inches by 6½in, and develops 90 horsepower at 1000 revolutions per minute. The pump is designed to deliver 1000 gallons per minute. The pump is geared up from the engine at 1¾ times engine speed by means of a shaft and gearing from the front end of the change speed box, the gears enclosed and running in oil.

The pump is put out of gear when travelling on the road. The turbine pump is a Roes Roturbo twin impeller multi-stage type. Special arrangements are made to cool the engine when pumping at full power for some considerable time. A two-way valve is provided on the turbine pump delivery for the purpose of directing a supply of water under pressure into one of two filters, either of which can be cleaned whilst the other is in operation.

From those filters the water passes through the radiator into the engine circulation. One man can take full charge when travelling on the road, and can control both engine and pump when at a fire.

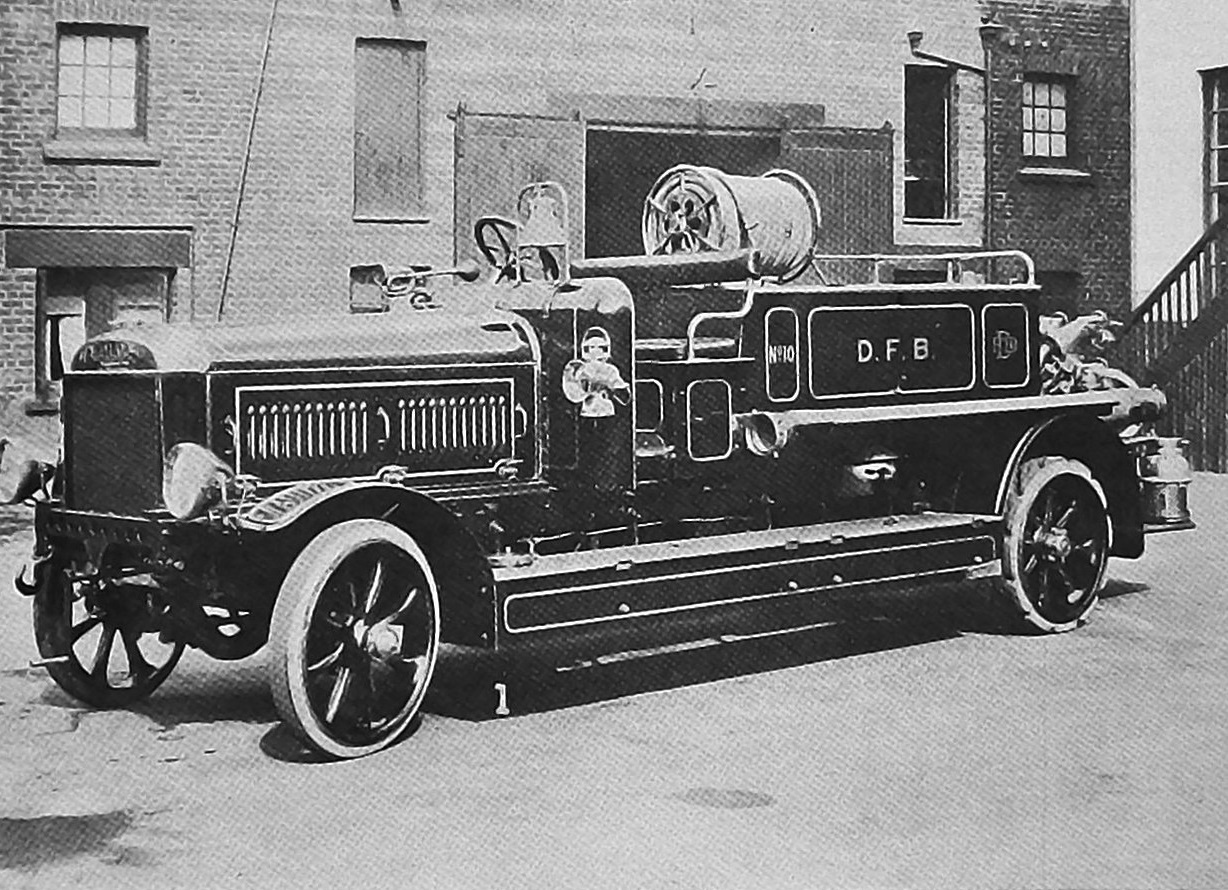

The priming gear consists of a gun-metal rotary pump driven through frictional gearing at the rear end of the gear-box, connected by a large-core copper pipe to the delivery side of the main pump. An automatic ball valve throws the pump out of gear when water is obtained. The suction hose consists of 36ft of flexible hose, five-ply rubber, smooth bore, with internal wire covered and external wire in view. This is in two 10ft lengths carried in troughs along the sides of the body of the machine, and 8ft lengths carrried in side lockers.

The delivery is of gun-metal with two branches. The valves are of the automatic quick closing type, and the branch ends are fitted with 2½in Morris couplings.

The first aid apparatus of tank and hose reel used in conjunction with the main pump is furnished with polished brass ends and 180ft of 1in four-ply india-rubber hose in 60ft lengths, fitted with brass connecting screws with 1in standard gas threads.

The reel is placed so that the hose can readily be run off from either side. The hose is permanently attached to the centre of reel, and furnished at its outer end with a hand-controlled branch. The tank is of sheet brass with a capacity of 40 gallons. The body of the machine is constructed of thoroughly seasoned hardwood, free from dead and loose knots, shakes, warps and other defects. It is designed so as to be independent of the main frame to give access to the chassis.

The floor is made detachable to facilitate oiling of the gearing etc, and the top is sloped so that water will drain off. Long side doors are fitted, hinged at the top and fitted with catch bars when open. The approximate length of the machine is 21ft 4in, width 6ft 9in, wheel base 13ft 9in. — ODT, 26.2.1925

Compiled by Peter Dowden